Products

Quiénes somos

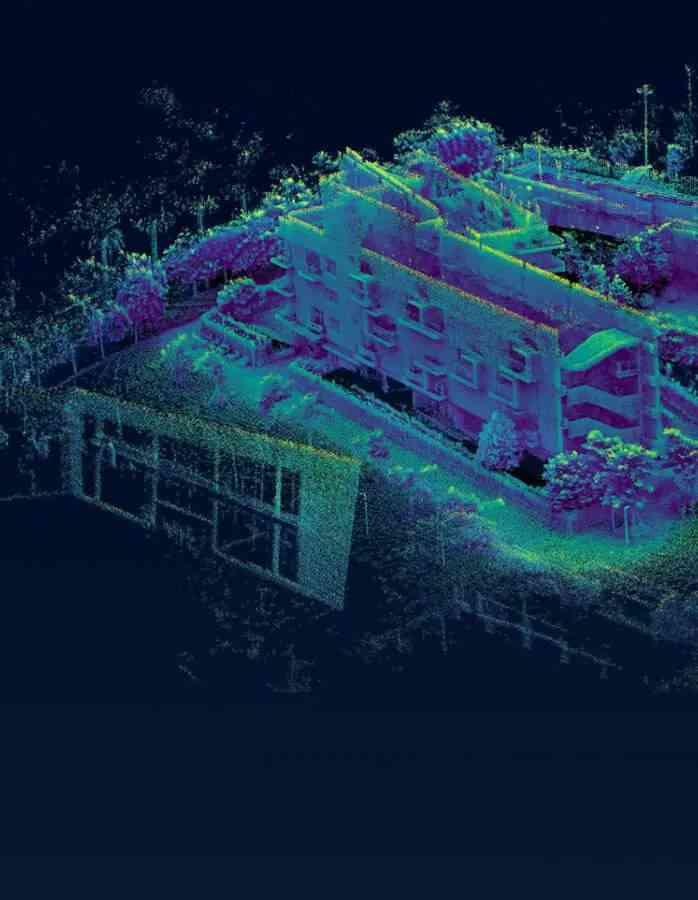

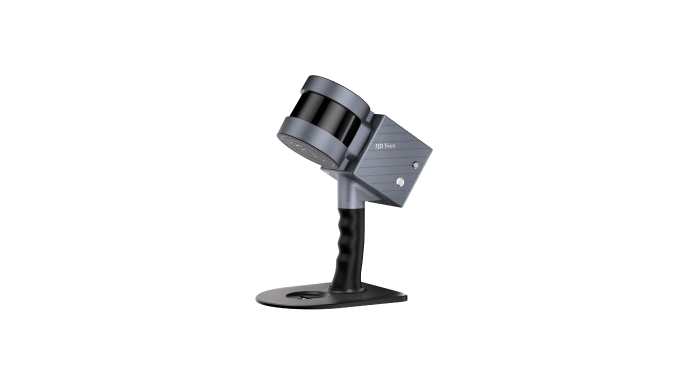

FJDynamics es una empresa de robótica centrada en la digitalización, la automatización y las nuevas energías. Estamos comprometidos con la creación de robots prácticos y asequibles para las industrias más intensivas en mano de obra y el uso de nuestra tecnología para impulsar la adopción de la inteligencia artificial en todos los sectores para mejorar la productividad y el entorno de trabajo. En la actualidad, nuestras soluciones se aplican ampliamente en la agricultura, el paisajismo, la construcción, la topografía y los servicios de instalaciones. A medida que nuestro negocio se expande por todo el mundo, nos entusiasma colaborar con socios y clientes para crear un futuro mejor para el mundo.

10+

Oficinas

En todo el mundo

60%

I+D

Miembros del equipo

1500+

Asociados

En todo el mundo

800+

Patentes

de

invención